Welding, cutting and grinding: Minimize risks associated with occasional hot work

By Alexandra Skinner/WorkSafeBC

Photo: Adobe Stock

In B.C., a construction worker was using a special glue to lay vinyl lining on a floor — and using a heat gun to install the floor covering. As he was warming up the heat gun, there was a sudden explosion, and the worker’s face was seriously burned.

The explosion — which was caused by the heat from the heat gun combining with vapours from the glue — helps to demonstrate the risk to workers doing “hot work.”

“Hot work” is any task that involves burning, welding, riveting, grinding, or using fire- or spark-producing tools, or other work that produces a source of ignition. It has the potential to spark fires or explosions, ranging from a small fire to a massive explosion.

“If you are engaging in hot work, or hiring contractors to perform tasks like cutting, grinding, welding, or using heat guns – you need to be aware of risks,” says Jose Barranco, a manager in WorkSafeBC’s Risk Analysis Unit. “It’s your responsibility to talk to that contractor and ensure the work does not introduce the risk of fire or explosion.”

Occasional tasks pose increased risk

Employers or workers who continually work with machinery or tools where hot work is common are well versed on the potential for fire and explosion and understand the importance of safety processes and procedures.

But hot work is also conducted outside of industrial settings by employers unfamiliar with the nature — and risks — associated. Even small businesses like offices, restaurants, or retail operations may require occasional hot work, for tasks including the following:

- Building maintenance and repair services

- Machinery and equipment repairs

- Plumbing and HVAC maintenance

- Installation of torch-applied roofing

- Electrical work

- Landscaping and tree trimming services

- Installation or repair of metal structures like railings or fencing.

- Thawing frozen pipes

Employer responsibilities

“Even when hot work is a rare occurrence in a workplace, employers are still responsible for keeping their workers safe. This means thinking about what might cause harm to workers and taking reasonable steps to prevent that harm from happening,” says Barranco.

If hot work is necessary at a workplace — even occasionally — employers must comply with their provincial health and safety requirements. In B.C., the Occupational Health and Safety Regulation (OHSR) sets out requirements for the safe execution of hot work activities in the province.

Provisions should include:

- Fire watches: A designated person must monitor the hot work area for fire hazards and prevent or extinguish any fire.

- Equipment: Hot work equipment must be properly maintained and in good working order.

- Ignition sources: All potential ignition sources must be identified and controlled before hot work can begin.

- Ventilation: Adequate ventilation must be provided to prevent the buildup of flammable or toxic gases.

- Fire protection: Adequate fire protection must be provided and readily available.

- Emergency response: A plan for responding to an emergency must be in place and known to all workers involved in the hot work.

B.C.’s OHSR also includes requirements for permit systems, training, and record-keeping to ensure the safe execution of hot work activities.

The fire triangle

Employers need to understand the types of work that could cause fires or explosions – and look out for flammable or combustible materials that are present or introduced into the work site.

The fire triangle or combustion triangle is a simple model for understanding the necessary ingredients for most fires. The triangle illustrates the three elements a fire needs to ignite: heat, fuel, and an oxidizing agent (usually oxygen). A fire naturally occurs when the elements are present and combined in the right mixture.

“Hot work has the potential to unite all three parts of the fire triangle – creating a risk of fire and explosion as hot work introduces an ignition source,” says Barranco.

Before work begins, look at the area surrounding the worksite and identify materials that could potentially catch fire. Some are more obvious, like pressurized gas tanks, containers with fuel, or cleaning agents, which may release flammable vapours. Others may be less obvious, like combustible materials, including paper scraps, oily rags, wood dust — or any other organic dust like coffee powder, plastics, cardboard, plywood, greases, or lubricants.

“Many hot work incidents occurred simply because workers didn’t know flammable vapours were present, like the construction worker who was injured laying flooring,” says Barranco. “They were not aware the vapours from the glue were flammable.”

Barranco advises that employers should remove combustible materials from the area where work is being performed. “In some cases, it may be less practicable to remove these materials, but there are ways to protect the area, such as covering them with a fireproof tarp,” he adds.

Use a Hierarchy of Controls to Reduce the Risk

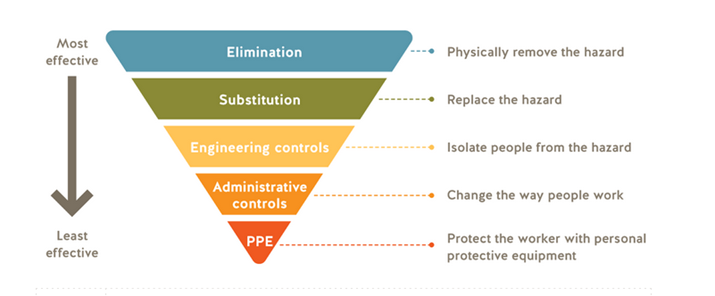

When considering how to reduce the risk, there is a certain order employers and workers should follow — called a hierarchy of controls.

Note that while the controls are listed in order of effectiveness, all four types of controls should be considered – and often work best in combination.

Employers should always engage with workers when looking at the hierarchy of controls.

- Find alternatives: Implement safer alternatives to hot work where possible (e.g., cold cutting, replacing instead of repairing).

- Clear the area: Clear flammable or combustible materials away from hot work, and/or use barriers to protect areas where sparks and hot debris from hot work could result in a fire or explosion.

- Coordinate contractor activities between worksites: Be aware of the proximity of work tasks being conducted. This includes being aware of ventilation systems in place that could potentially connect flammable materials with hot work activity between separate worksites.

- Test and monitor: Test and continuously monitor the area for flammable or explosive substances. Use gas monitors where appropriate.

- Ventilate the area: Make sure the workplace has adequate ventilation to help reduce the buildup of flammable or explosive gases or vapours.

- Prepare tanks and drums: Make sure tanks and drums are prepared for hot work, taking steps such as emptying, cleaning, gas freeing, inerting, or isolating the tanks.

- Establish fire watches: It is crucial to have a person whose job is to look for any potential smaller, new fires that could spark — even after the work is done. In some cases when you are doing welding or other hot work, sparks can take a few hours to smolder enough to generate a fire. Have someone look in during the task, and a few hours after the work is finished, for any evidence of fires or smoldering.

- Have fire extinguishers ready: Make sure the appropriate types of fire extinguishers are available wherever hot work is done, and ensure workers know how to find and use this equipment.

For more information on reducing the risks of hot work, visit WorkSafeBC.com.

In addition, there are many resources available to employers through the Canadian Centre for Occupational Health and Safety and the National Fire Protection Association.

Alexandra Skinner is the manager, government and media relations, at WorkSafeBC.